Recently, the Standard relating to kitchen exhaust fan casings and cowls for commercial buildings was updated. As there has been some confusion regarding Section 6.2 of AS/NZS 1668.1 2015, Fantech has sought an interpretation from the committee responsible for this Standard.

Clause 6.2.5 of AS/NZS 1668.1 2015 “The use of ventilation and air conditioning in buildings – Fire and Smoke control in buildings” states:

“Where kitchen exhaust fans are located within the building envelope, fan casings and cowls shall be manufactured from materials that are not deemed to be combustible and that have a fusing temperature above 1000°C.”

The equivalent clause 11.2.5 in AS/NZS 1668.1 1998 Amendment 1 states:

“Kitchen exhaust fan casings and cowls shall be manufactured from non-combustible materials that have a fusing temperature above 1000°C.”

Background Information

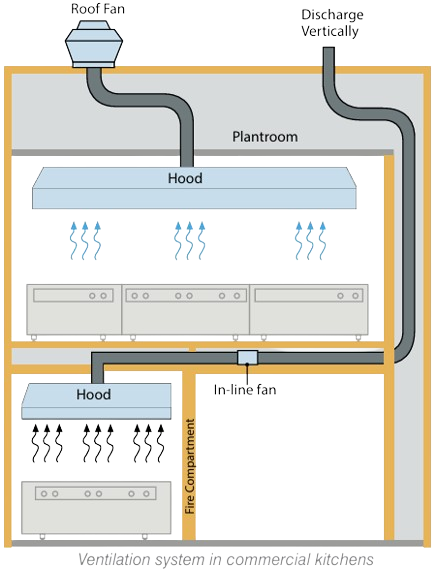

In a kitchen exhaust system there are two potential sources of fire – a fire within the duct itself and a fire within the compartment served.

If the kitchen exhaust ductwork is not well cleaned, grease can line the duct walls along its complete length. Because this ductwork may pass through other areas of the building, the requirement for metal construction is to stop a potential fire from spreading, and importantly, escaping through the duct walls. This is particularly important as fire dampers cannot be used in kitchen exhaust ductwork.

The supporting commentary within Clause 6.2.5 of AS/NZS 1668.1 2015 states that the integrity of the exhaust duct and fan within the building and to the point of discharge, is critical to containing a fire within the duct system.

Fan Casings and Cowls

The 2015 standard requires that the fan casings and cowls be made of non-combustible materials (e.g. metal) if “within the building envelope”. The intent is that fans should have similar protection to that of sheet metal duct to stop the spread of fire to other areas of the building.

Clauses 6.2.5 makes an allowance for minor penetrations, such as small plastic fittings, electrical conduit, gaskets, and grommets on the fan’s casing, as it states that these components are not considered to affect the fusing temperature of the casing.

It is important to note that components inside the fan (such as impellers) are exempt from this requirement - therefore plastic components inside the fan are allowed. The temperature of kitchen exhaust airstreams are generally lower than 60°C and therefore plastic components inside the fan are typically able to handle the temperatures encountered.

Building envelope

AS1668.1 2015 Clause 6.2.5 (Draft Amendment 1) has been revised to better define the intent of the term “building envelope” as follows:

“Where kitchen exhaust fans are located inside the building, fan casings and cowls shall be manufactured from materials that are not deemed to be combustible and that have a fusing temperature above 1000°C.”

Therefore, metal casings and cowls for kitchen exhaust fans are only required when installed within the building. This would apply to in-line fans below the roof line.

As previously mentioned, a kitchen exhaust system is designed to stop the potential spread of fire to another part of the building. Therefore the rationale behind this clause is to contain the fire within the fan and duct system.

As roof mounted fans are above the roof line (and are unlikely to spread a fire to another part of the building) they are not required to comply with Clause 6.2.5 and therefore do not need to be made of metal, unless being used as part of a smoke spill system. It is important to note that the BCA is a minimum performance standard and designers can choose to exceed these requirements.

BCA Volume One 2016 references AS/NZS 1668.1 2015 and therefore complying with the above clauses will meet the Deemed-to-Satisfy solution requirements of the BCA in this matter.