In 2013, an independent report highlighted that 70% of the $1.1 billion per annum productivity gains delivered by Australian Building Codes Board (ABCB) reforms were derived from the current performance-based code. The report also identified that future gains are possible if there is an increased use of Performance Solutions. This Technically Speaking article aims to summarise the steps required to submit a performance solution to the National Construction Code (NCC).

The NCC sets the minimum requirements for the design, construction and performance of buildings throughout Australia. In order to meet the performance requirements either a performance solution or a Deemed-to-Satisfy (DtS) solution must be worked through. It is important to note that both methods can be used to prove compliance with the performance requirements.

Many in the industry believe that following the DtS provisions are the best way to comply with the NCC. However, because the DtS provisions are generic by nature and need to be relevant for a wide range of building types, they are often conservative and can lead to unnecessary costs in a building project. In fact, some experts believe that many of the DtS provisions in the NCC have no evidence that supports they meet the all-important performance requirements. The ABCB is currently conducting a campaign to encourage the use of performance solutions as this will lead to significant improvements in productivity.

One example where performance solutions can lead to cost savings is the installation of Jet fans. They can lead to reduced excavation depths for car parks, often require no ducting or perimeter exhaust plenums, have simplified wiring, reduce the controls expertise required on site, and increase the number of available car park spaces. While there is increased engineering analysis required to show compliance with the performance requirements, construction cost savings and additional building revenue of over $1 million in some larger projects have been realised.

Other examples of where performance solutions may be used in ventilation systems include:

- Using the Indoor Air Quality Verification method to determine airflows required based on maximum contaminant levels.

- Within car parks, showing that vehicle exhaust contaminants are within certain limits, that sprinklers are not adversely affected by jet fans and that occupant safety during evacuation is not affected.

- Demonstrating that plastic ducting meets the NCC performance requirements in regards to fire.

Case study: Process for a car park ventilation system using multiple jet fans

The first step is to identify the performance requirement that needs to be met, and in this case it is FP4.4 as shown below.

To meet performance requirement FP4.4 we can choose to follow the Deemed to Satisfy solution F4.5 Ventilation of rooms or conduct a performance solution.

The DtS solution F4.5 states that we must use

- Natural ventilation complying with DtS Clause 4.6; or

- A mechanical ventilation or air-conditioning system complying with AS 1668.2 and AS/NZS 3666.1.

Therefore, for mechanical ventilation we could design a system according to AS 1668.1 and AS/NZS 3666.1. However, as AS1668.2 only allows for single jet fans serving dead spots of a carpark, we cannot complete a DtS solution for this scenario.

For a performance solution we need to show that we meet FP4.4.

In order to help the engineer understand what is deemed acceptable in limiting the “accumulation of harmful contamination by micro-organisms, pathogens and toxins”, verification method FV4.2 has been created to define these limits.

FV4.2 Verification of suitable indoor air quality for carparks

For a Class 7a building, compliance with FP4.3 and FP4.4(a) is verified when it is determined that the building is provided with sufficient ventilation with outdoor air such that carbon monoxide exposure levels do not exceed the limits specified in Table FV4.2.

Table FV4.2 Maximum carbon monoxide exposure for carparks

| Concentration, ppm |

Total exposure duration per day |

| 100 |

Not to be exceeded |

| 90 |

15 minutes |

| 60 |

1 hour |

| 30 |

8 hours |

Note: Various government work, health and safety regulations specify workplace exposure limits for airborne contaminants in the workplace.

FV4.2 states that a car park shall not exceed a carbon monoxide exposure over a 1 hour time period of 60ppm

We may then:

-

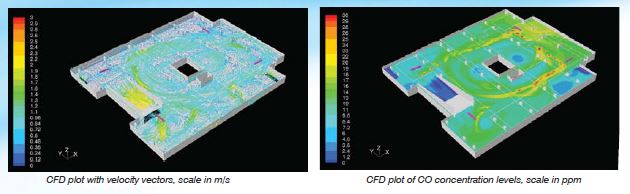

1. Meet with the project stakeholders to agree on the assessment method that will be performed to show compliance. The stakeholders would most likely agree that a CFD analysis would comply with the Evidence of Suitability assessment method using the limits shown in verification method FV4.2. The stakeholder meeting may also agree on CO generation rates to be used in the analysis, the peak number of car movements, exhaust and supply airflow rates and the height at which the CFD analysis should be undertaken.

-

2. The CFD analysis would then be conducted and evaluated to show that the performance requirements have been met. If the performance requirements are not met (60ppm CO level over 1 hour) the fans may be moved to different locations and the CFD would be re-run until the performance requirements are met.

-

3. The last step would be to generate a report showing that the performance requirements have been met.

For more information on the NCC and performance solutions visit the ABCB site at www.abcb.gov.au.