The AirLink Integrated Variable Air Volume (VAV) system is the next step in efficient HVAC system design. This modern system is based on electronic VAV diffusers working with an even pressure duct design. The system removes the need for air flow hood measurements as all air balancing is performed by the optional air flow sensor built into each diffuser, and the centrally located Rickard software or Building Management System (BMS).

VAV Diffuser Air flow sensors - How it works?

The Rickard air flow sensor uses a sensitive air flow cross meter at the neck of the diffuser and a highly accurate pressure sensor to measure total pressure. The Rickard control system uses the total pressure, VAV position and known neck diameter to calculate the air flow being delivered. This method is very stable over varying temperatures and is further supported by Rickards software that factors in the buildings altitude. The system is equal in accuracy to a traditional measuring hood.

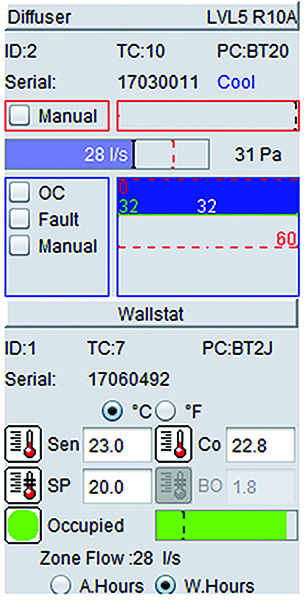

VAV diffusers can report the precise air flow at every grille and/or operate in an adaptive mode where the diffusers will open and close to maintain selected minimum and maximum air flow settings. This enables electronic commissioning to be conducted by a technician who is connected to the diffuser network via a laptop computer. The technician balances the VAV system by keying in the required air flows, which programs the diffusers to operate at their required specifications. The BMS can use this technology to monitor air flows in each room within the building and allow remote maintenance that eliminates disruptions to building occupants.

Commissioning Tool Software

Commissioning Tool Software

VAV Diffusers - Electronic Air Balancing

To balance an AirLink VAV System, technicians use the free software tool to drive all diffusers fully open. A simple Wizard is used to activate all electronic VAV diffusers. The total pressure and air flow moving through the diffuser is then read via the computer and/or BMS. The air flow at the index diffuser (last diffuser in duct run) must be set first by adjusting the air flow output from the Air Handling Unit (AHU) or Pressure Controlled Damper (PCD).

Design Tips

- The pressure sensor controller in this system must be 2/3 down the duct run.

- The pressure across all the diffusers should be relatively even.

- The diffuser's neck diameter must not be oversized as this will cause excessive pressure loss at the start of the duct run.

Once the correct air flow has been achieved at the index diffuser, then all other diffusers can have their adaptive air flow controls activated and the minimum/maximum air flow values entered. This can be conducted via the same software Wizard. The diffusers will now automatically adjust the air flow entering the zone according to the set point and the demand within the space.

Further adjustments will not be required as the diffusers will automatically monitor and continuously balance the air flows. If the AirLink system is connected to a BMS, it can monitor every diffuser's total pressure and the air flows entering each zone for the life of the building.