Fan manufacturers can choose to publish either ‘In-Duct’ or ‘Free-Field’ noise levels depending on where the noise is measured. The difference between the two terms is not well understood by many engineers and can lead to underestimation of noise levels.

What is 'In-duct' and 'Free-Field'?

‘In-duct’ noise is a measurement of the sound inside the duct. The International test standard used is ISO5136 (which is identical to BS848-2.5).

‘Free-Field’ noise is a measurement of the sound outside of the duct. The relevant International test standards are ISO13347-1, 2, 3 and 4.

Therefore, if the sound power level of a ducted fan is measured outside the duct, it is a free-field measurement.

What is an end reflection?

The sound energy emitted into the duct from fan equipment is not always fully transmitted into a test room. This prevention of the sound energy being transmitted into a room is called an end reflection. Because of this, the sound power measured in the room may be lower than the true sound power of the fan equipment.

How should fans be tested?

Fans may be tested to various noise test standards. The series of International Standards are: ISO13347 Parts 1 to 4 and ISO5136.

ISO13347-1 2004 “Industrial fans - Determination of fan sound power levels under standardized laboratory conditions Part 1: General overview”. Clause 7.1 states: “If a fan has a duct on the inlet and/or outlet side, then the sound power levels on the sides which are ducted should be determined by an in-duct method as detailed in ISO5136:2003. As an alternative method with a lower order of accuracy, an enveloping surface, sound intensity or reverberant room method may be used with corrections added for the effect of duct end reflection. Where figures are obtained in such an alternative method (e.g. for small duct sizes or for other reasons) then this shall be clearly stated.”

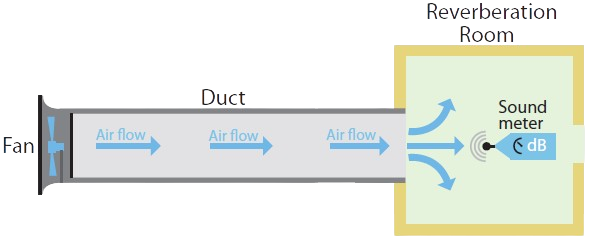

Figure 1 and Figure 2 show an example of a Type B installation (Free inlet, ducted outlet) and how an in-duct method (Figure 1) or a free-field method (Figure 2) would be measured.

The means of converting a free-field measurement to an in-duct measurement is by adding an end reflection coefficient (although this is still less accurate than testing using the in-duct test method).

Figure 1: 'In-duct' noise measurement of a fan to ISO5136. Note that the noise is measured in the duct.

Figure 2: ‘Free-Field’ noise measurement to ISO13347-2. Note that the duct terminates at the wall inside the room and the noise is measured in a reverberation room. Therefore, less sound energy is measured when compared to the sound level using the In-duct method as shown in Figure 1.

ISO13347-1 defines theoretical end reflection coefficients based on different conditions. Where circular duct terminates flush with a wall as per Figure 2, the end reflection coefficients are as shown in Table 1.

Table 1: End reflection values based on flush mounted circular ductwork from ISO13347-1.

| Frequency Bands |

| Fan Dia. (mm) |

63 |

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

| 310 |

12 |

7 |

3 |

1 |

0 |

0 |

0 |

0 |

| 400 |

10 |

5 |

2 |

0 |

0 |

0 |

0 |

0 |

| 500 |

8 |

4 |

1 |

0 |

0 |

0 |

0 |

0 |

| 560 |

8 |

3 |

1 |

0 |

0 |

0 |

0 |

0 |

| 630 |

7 |

3 |

1 |

0 |

0 |

0 |

0 |

0 |

| 710 |

6 |

2 |

1 |

0 |

0 |

0 |

0 |

0 |

| 800 |

5 |

2 |

0 |

0 |

0 |

0 |

0 |

0 |

| 1000 |

4 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

| 1250 |

3 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

| 1400 |

2 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

| 1600 |

2 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| 1800 |

2 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| 2000 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Note: If duct protrudes into a room (instead of being flush with the wall), the end reflection values will be greater than shown above.

Example using a Ø400mm axial fan.

| Frequency Bands |

|

63 |

125 |

250 |

500 |

1000 |

2000 |

4000 |

8000 |

| Free-field Sound Power |

58 |

65 |

68 |

69 |

71 |

69 |

61 |

52 |

| Theoretical End Reflection |

10 |

5 |

2 |

0 |

0 |

0 |

0 |

0 |

| In-duct Sound Power |

68 |

70 |

70 |

69 |

71 |

69 |

61 |

52 |

In other words if the sound test data for a smaller than 2 metre diameter fan is based on the free-field method, the sound power levels will always be lower than if the same fan was tested using the in-duct method.

However, ISO13347-1 warns that with the present state of knowledge the end reflection coefficients are approximate only, and wherever possible in-duct sound power levels based on test method ISO5136 should be used for greater accuracy.

Why is this important?

Firstly, if an engineer is comparing noise levels on similar fans from different manufacturers that use different test methods, (in-duct vs free-field) the sound level comparison will be inaccurate.

Secondly, when performing an acoustic analysis, an acoustic engineer expects to use in-duct sound power levels for fans in a ducted system. If the engineer is unaware that the data is based on the free-field method, the acoustic analysis will under predict the noise levels at the critical low frequencies. As most noise problems with fans occur at the 125Hz and 250Hz frequency bands, noise problems may be experienced if free-field sound levels are used in error.